Based in Newcastle, APEC Inspection are a trusted Level 3 testing and inspection solution. Certified to ISO/IEC 17025:2017 (Testing and Calibration) by the National Association of Testing Authority (NATA), we offer a range of services to ensure your plant and equipment meet the safety and efficiency demands of your industry.

APEC also provides certification services covering both Australian and international standards, with experience in various industries, including underground mining testing and inspection. We can help you reduce your risk and ensure compliance with your industry’s standards. Our service capabilities extend right across the industrial testing and inspection spectrum. In addition to our primary services detailed below, we also offer solutions and advice in:

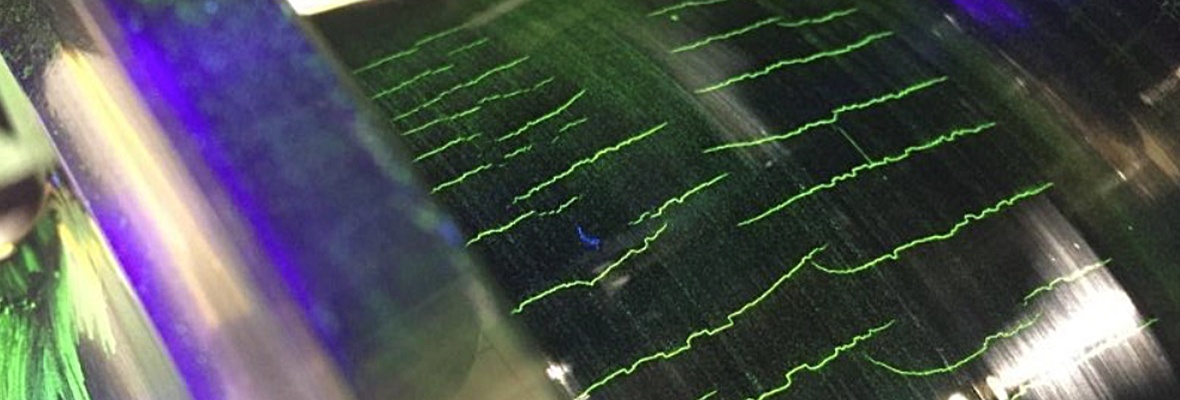

Magnetic Particle Inspection (MPI) is a non-destructive testing (NDT) process used for the detection of surface and shallow subsurface (near surface) defects and discontinuities in ferromagnetic materials."

Ultrasonic Inspection (UT) is a non-destructive testing method which uses high frequency sound energy to conduct sub-surface and surface examinations and make measurements. The ultrasonic vibrations pass through the material and are reflected by any imperfections or defects that are present.

APEC Inspection Service has added positive material identification via LIBS analyzer to its list of testing services. Laser Induced Breakdown Spectroscopy (LIBS) is a powerful, nondestructive technique for measuring elemental composition of metals including carbon content of Fe and SS alloys as well as PMI of Ni, Ti, Cu, Co and Al alloys.

Phased Array Ultrasonic Testing (PAUT) technology has become the established method for advanced NDT testing applications. Phased Array Techniques allow the user to cover a wider volume of inspection; such as being able to cover the complete span of a weld or part without the need to move or reposition the transducer.

Contact us today and we’ll get back to you within 24 hours to discuss how we can help with your testing and inspection requirements.

© apecinspection.com.au. All Rights Reserved. Designed by Peritus Digital